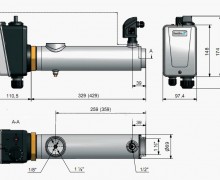

Plate heat exchanger BEHNCKE TSC 510 / TSC 910

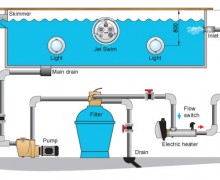

Energy-saving and innovative low-temperature heat sources. The energy of the future. Maintaining an ecological balance for future generations especially for leisure needs is the decisive challenge for BEHNCKE‘s technicians. The points were therefore set at an early stage for the development of products in the energy intensive sector of heat generation. Then as now, efficiency, energy-saving and high quality standards were the goal-orientated targets for BEHNCKE. Through resolute process optimization and detail optimization BEHNCKE‘s plate heat exchangers are regarded today as being among the most efficient products in this segment. BEHNCKE screw fastened plate heat exchangers. The most efficient way to heat a swimming pool with low temperature technology. BEHNCKE plate heat exchangers are high performance components that have an enormously large heat transfer area on account of their special design. This way, with a primary flow of only 50°/30°, a swimming pool can be heated constantly and also extremely cost efficiently. In particular they are suitable for connection to low-temperature boilers, solar systems/solar absorbers and heat pumps. Due to the variably designed connection possibilities an almost unlimited compatibility with a wide range of different energy sources results, e.g. in the form of a smart bypass solution in the filter circuit. Flexible usage and ease of maintenance thanks to the screw fastening technique. The majority of the plates are available in various embossment types and sizes. This enables individual requirements of the flow speed in relation to the flow rate and heat exchange output to be realized. The embossed plates are available in the grades AISI 304, AISI 316 and titanium, the maximum working pressures being 10 bar, independently of the material. The screw fastening of the individual plates also enables easy maintenance, providing for a long and constant service life.

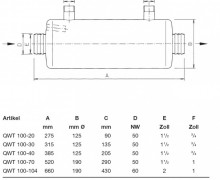

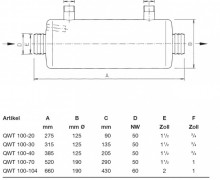

Full equipment. Useful accessories. Modular design. Extremely easy installation. Currently 4 standard types are available, which differ in terms of their respective output coeffi cients. Easy-to-handle installation is ensured by the modular design of the system components.

As a fully installed compact system the plate heat exchangers are equipped with the following:

• Circulation pump

• Check valve

• 2 shut-off valves

• 2 PVC ball valves

• Shut-off valve with drain

• PVC T-piece with thermowell (for accommodation of a temperature sensor)

Each plate heat exchanger can be optionally integrated into the digital pool control unit ‘BEHNCKE Control 1.2’ (pre-installed). To act optimally against heat diffusions, BEHNCKE’s technicians have developed the ISO box, which is exactly geared to this. The plate heat exchangers are also available in titanium to meet the most demanding of requirements, with a 5-year corrosion warranty. Individual con� guration options. Extremely variable areas of application. Positive energy balance. With low maintenance costs. Due to their uncompromising high-quality design BEHNCKE plate heat exchangers are also excellently suited—in addition to their use in private swimming pools—for applications in the public or industrial sectors. For these very specifi c requirements, frames, plates and seals are also available in various material fi nishes, so that, depending on the fl uids and operating conditions that are being treated, the appropriate legally prescribed directives can also be met. Great emphasis has therefore been placed, for example, on a long service life for small items such as seals, while unrivalled low maintenance costs have been achieved thanks to the easy replacement of the plates without the use of special tools. This guarantees an absolutely positive degree of commercial effi ciency particularly with regard to cost-sensitive requirements. And to match the equipment as well as possible to the relevant requirements of the customer BEHNCKE’s engineers are available as expert and motivated contact persons to answer any queries that relate to the planning and execution.

Model | TSC 510 | P 15 HH | TSC 510 | P 27 HH | TSC 910 | P 23 LL | TSC 910 | P 31 LL |

| Wattage | 35 kW | 15 kW | 70 kW | 30 kW | 104 kW | 52 kW | 140 kW | 70 kW |

| Primary in/out | 50/30°C | 40/30°C | 50/30°C | 40/30°C | 50/30°C | 40/30°C | 50/30°C | 40/30°C |

| Secondary in/out | 15/35°C | 15/35°C | 15/35°C | 15/35°C | 15/35°C | 15/35°C | 15/35°C | 15/35°C |

| Primary flow rate | 1,52 m³/h | 1,30 m³/h | 3,00 m³/h | 2,60 m³/h | 4,57 m³/h | 4,50 m³/h | 6,10 m³/h | 6,10 m³/h |

| Secondary flow rate | 1,51 m³/h | 0,65 m³/h | 3,00 m³/h | 1,30 m³/h | 4,53 m³/h | 2,24 m³/h | 6,04 m³/h | 3,02 m³/h |

| Primary pressure drop | 0,10 bar | 0,05 bar | 0,10 bar | 0,05 bar | 0,25 bar | 0,25 bar | 0,25 bar | 0,25 bar |

| Secondary pressure drop | 0,10 bar | 0,05 bar | 0,10 bar | 0,05 bar | 0,25 bar | 0,25 bar | 0,25 bar | 0,25 bar |

| Max.working pressure | 6 bar | 6 bar | 6 bar | 6 bar | 6 bar | 6 bar | 6 bar | 6 bar |

| Connections | 4 x 1 1/4'' | 4 x 1 1/4'' | 4 x 1 1/4'' | 4 x 1 1/4'' | 4 x 1 1/4'' | 4 x 1 1/4'' | 4 x 1 1/4'' | 4 x 1 1/4'' |